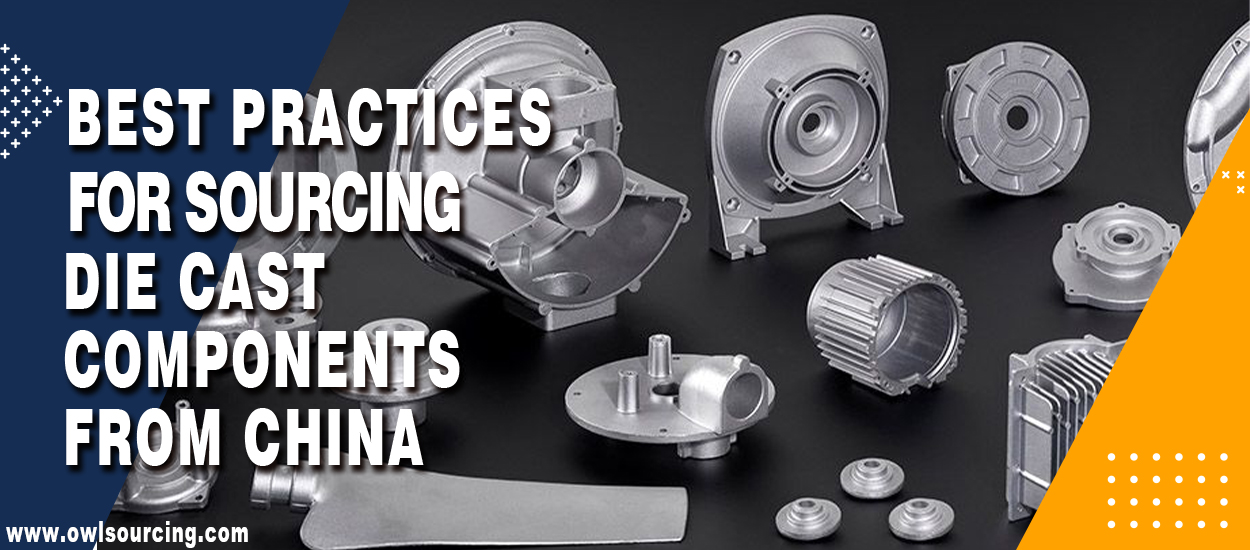

If you need die-casting services, China is the best option. It is the global leader in die-casting.

In my experience as a sourcing agent, I’ve observed:

- Many international companies are choosing Chinese suppliers for their die-casting needs

- Chinese suppliers often provide competitive pricing for die-casting components

- Manufacturers can handle simple to complex die casting projects

- China’s well-established supply chain network and logistics infrastructure ensure timely delivery

But we aren’t here to discuss why China is an ideal choice. I will discuss the die-casting process and how to get die-cast components from the best Chinese suppliers.

An Overview of the Die Casting Process

Before you go to hire the services, what does die casting entail? Knowing the entire process ensures that you get the best sourcing experience.

What is Die Casting?

Die casting is an advanced and effective manufacturing process. It involves injecting molten metal into a high-pressure mould cavity.

This process is suitable for mass-producing complex shapes with high precision and finishes. It also produces parts that require tight tolerances and intricate designs.

Benefits of die-casting

Die Casting is an innovative manufacturing technique. But why is the innovation becoming so well-known? Here are the benefits of the industrial components die-casting:

- High-quality products by this method have a longer service life.

- Die casting produces several bulk metal parts.

- Die Casting is fast and seamless. Moreover, little maintenance is needed for die-casting tools.

- The process can make any texture, shape, size, or lustre possible.

- It has a high degree of accuracy.

- Die casting costs less since there is only one production process.

- The process creates less waste material and scrap.

Even if you know much about die casting, it can be hard to source it. It is particularly important when working with overseas suppliers.

OwlSourcing can help! We know the Chinese manufacturing sector thoroughly. Our team is expert enough to handle the whole sourcing process. You can relax knowing your die-casting projects are in good hands.

How to Find the Right Die-Casting Manufacturers in China?

The process is daunting if you have no idea how to proceed, especially when you are unfamiliar with the Chinese language, uncertain about factory capabilities, and risk doing business with trading companies rather than genuine manufacturers.

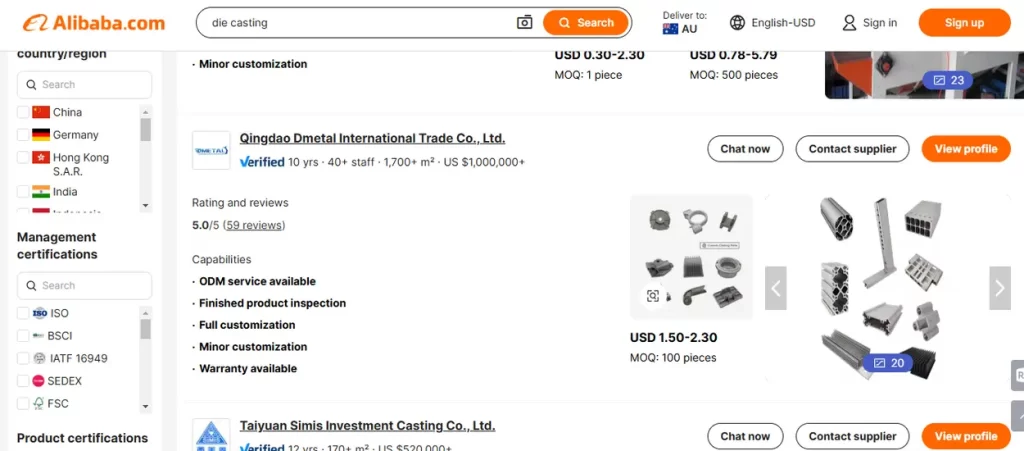

The majority of buyers are deceived by choosing suppliers solely from low prices listed on websites like Alibaba, without even thinking about added costs, poor quality parts, or late shipments.

Issues do not stop there. Dimensional issues such as porosity, dimensional inaccuracies, and irregular surface finishes are not uncommon without proper controls.

Communication breakdowns can lead to misunderstandings about technical diagrams, shipping schedules, or payment processes.

Verifying whether a factory truly possesses the necessary expertise, equipment, and certifications (such as ISO 9001 or IATF 16949) is challenging from a distance, and this is before considering issues related to intellectual property, unclear logistics, and the inability to conduct on-site audits.

Which is why relying on online directories alone is not enough for finding precision die-cast components.

To avoid costly mistakes, it is wise to let an expert China sourcing partner like Owlsourcing help you out. With solid experience in the die-casting industry, Owlsourcing connects you directly with vetted, real OEM manufacturers.

They conduct audits of suppliers, quality inspection, technical facilitation, and shipping as well, all for your support and guarantee.

Instead of gambling with unknown die casting manufacturers, you have a trustworthy team on the ground that ensures your components are made correctly, every time. Contact us now!

Major Regions in China to Find Die Casting Service Providers

Here are China’s top factory cities for sourcing die-casting services.

| Region | Die Casting Services | Benefits |

| Guangdong Province |

|

|

| Jiangsu Province |

|

|

| Zhejiang Province |

|

|

| Shanghai |

|

|

| Chongqing |

|

|

How to Guarantee Quality for Die-Cast Products Made in China?

Quality is a crucial aspect of die-cast production. Here are ways to ensure high-quality die-casting in China:

1) Hire Third-Party Inspection Services

Get a third-party quality inspection in China to perform quality checks at each production stage. The inspections ensure that defects or issues are spotted early and corrected.

2) Request In-House Quality Control Measures

Ensure the manufacturer has a robust in-house quality control system. This way, you can consistently meet your specifications. The system should include regular inspections, testing, and documentation.

Common Quality Standards/Certifications for Die Casting

| Certification | Description |

| ISO 9001 |

|

| IATF 16949 |

|

| TS 16949 |

|

| ISO 14001 |

|

| OHSAS 18001 |

|

| AS9100 |

|

| NADCAP |

|

How to Connect with Reliable Die-casting Manufacturers in China

So, how do you find reliable die-casting manufacturers? Here are several routes that can ensure you find a trustworthy supplier:

1) Research and Verification

Research potential manufacturers through Chinese wholesale websites like Alibaba or 1688. Vet their credentials, certifications, and customer reviews. Prioritise manufacturers with a proven track record.

As I’ve described above, this approach is not 100% safe. I’ve heard tons of tales about individuals who purchased serious quality issues despite choosing seemingly good sources on the internet.

Without on-the-ground verification and real-time quality control, there’s always some risk of getting something different from what you’re promised.

2) Factory Visits

Visit the factories to assess their working conditions. A factory visit allows you to see how the manufacturer operates.

This way, you know if their standards are on par with yours. Also, it helps you decide whether to proceed with the deal.

Note: Before placing a large order, request samples. It is an alternative to verifying Chinese vendors through factory visits. Evaluate the quality of their work.

Challenges in Sourcing Die Casting from China

Die casting is not perfect. It is subject to errors. Here are the common challenges in die casting and solutions:

1) Quality Issues

Die casting is effective; however, quality issues can happen. These issues include gas porosity and shrinkage, which can ruin a bulk order. Quality control measures must be undertaken to mitigate the quality issues.

Also, I recommend you communicate with the manufacturer. Regular inspections and clear communication can help address any problems promptly.

2) Communication Barriers

You can overcome language barriers by hiring bilingual staff. Use professional Chinese translation services to simplify the conversation.

Effective communication ensures that both parties understand the requirements and expectations. Precision die-casting industrial components demand proper communication.

3) Supply Chain Delays

Maintain close communication with your suppliers to plan for potential delays. It is also a good idea to have backup plans if delays occur. To avoid disruptions, keep track of production schedules. Hiring a global supply chain provider can solve this issue.

How OwlSourcing Helps Clients Find a Suitable Die-Casting Manufacturer in China

A US-based automotive parts manufacturer required a die-casting supplier in China. They wanted to produce aluminium alloy components for a new electric vehicle model.

Our team screened numerous die-casting manufacturers in China. We focused on regions with automotive manufacturing bases. So, we looked through factories based in Guangdong, Jiangsu, and Zhejiang. After evaluation, we recommended a reliable die-casting manufacturer.

Our team also negotiated favourable terms with the supplier, including:

- Competitive Pricing

- Flexible payment terms

- Quality control standards

- Timely delivery schedules

So, the client successfully partnered with the recommended die-casting manufacturer.

Steps Involved in the Die Casting Process

Now, I will cover the different stages of the die-casting process. You can see how the molten metal gets transformed into solid metal.

Step 1: Mould Preparation

The mould is cleaned and coated with lubricant. The lubricant facilitates the ejection of the cast.

It ensures that the molten metal flows smoothly. The finished part comes off easily without damage with lubricant.

Step 2: Injection

Manufacturers inject the molten metal into the cavity under high pressure. The pressure ensures the metal fills every part of the mould. This results in precise and detailed castings.

Step 3: Cooling

The metal cools and solidifies within the mould.

Step 4: Ejection

The cast part is now ejected from the mould. Ejector pins push the metal out of the mould cavity.

Step 5: Trimming

Excess material, called flash, is removed from the cast part. This step involves cutting away any extra metal. It may have seeped between the mould halves.

It is crucial to select a reliable service provider who executes each step. It ensures the highest quality and precision in the die-casting process. To verify this, consider hiring a sourcing agent to conduct factory visits.

The Materials Used in Die Casting

Die casting uses various types of materials and alloys. The metal you choose depends on the weight, budget, and other factors.

Nonferrous metals are used for this process. They have a trace or no amount of iron in them.

Aluminium die casting in China has grown in popularity. Likewise, zinc die-casting services are widely used in China. Other die-casting materials have unique properties that make them ideal for different applications.

Types of Die Casting Used in Industrial Settings

Die casting comes in several types. Also, suppliers often pick one or the other when manufacturing.

For the best products, knowing which die-casting type matches is vital. Here is an overview:

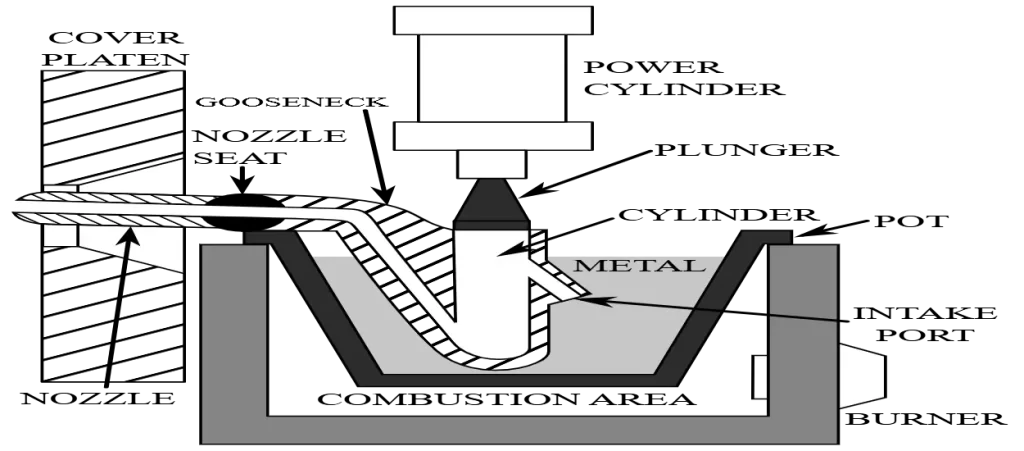

1) Hot Chamber Die Casting

Image Source: Wikimedia Commons

Hot-chamber die-casting is a popular option. It stands out in that the injection cylinder is fully immersed in the molten metal bath. Then, a gooseneck feeding system pulls the molten metal into the cavity.

This method’s perk over others is its high rate of production. It also facilitates quick ejection. However, a major setback is its high risk of corrosion.

2) Cold-chamber Die Casting

Cold-chamber Die Casting is like hot-chamber casting. The major exception is that this method prioritises minimising corrosion rather than efficiency. This method doesn’t need the injection system.

Instead, the molten metal is automatically fed to the cavity. It is ideal for metals that aren’t suitable for hot casting.

3) Other Die Casting Methods

While Cold-chamber and Hot-Chamber die-casting are well-known options, others exist. They are low-pressure, VPC, and squeeze die casting.

These options are less known in China’s die-casting factories. However, there are specific characteristics that make them ideal for some materials.

What Industries Need Die Casting Components

Die Casting is a common method in various industries. Here is an overview of the top three sectors that use it:

1) Automotive Industry

Automotive manufacturing relies on die-cast components. These components create engine blocks, transmission cases, and other structural parts. They must withstand high stress, making die casting an ideal manufacturing process.

2) Consumer Electronics

Die casting is often used to produce casings and internal components for devices. The process allows for the creation of lightweight and durable parts. Hence, custom die casting in China is a popular choice for consumer electronics.

3) Aerospace

This industry uses die-cast components for their lightweight properties. These details are essential for aircraft parts. Die casting offers the precision needed for critical aerospace applications.

Read More:

- Injection Moulding Cost in China

- Metal Stamping in China

- How to Manufacture Injection Moulds in China?

- Top 10 Die Casting Manufacturers in China

Final Thoughts!

Making die-casting industrial components in China has tons of benefits. You can save costs and purchase high-quality products.

I have discussed everything you need to handle the sourcing process. However, I understand how strenuous the China product sourcing process can be.

So, we offer an alternative – Product sourcing service. OwlSourcing provides competitive prices and friendly services. Contact us today to arrange your meeting with a die-casting supplier in China.