Packaging is not just for looks. It protects the product inside the box. If it isn’t of good quality, your item could break during shipping from China. A broken item due to packaging failure means money lost and unhappy customers.

Most importers trust the factory to take care of the packaging inspection. But mistakes are bound to happen all the time.

In some cases, you may use a dropshipping agent or buy from a Chinese factory directly. No matter your method, you must inspect the packaging quality. This step should be part of a good China sourcing process.

So, this guide is your go-to resource for navigating this process. It covers types of packaging quality inspections, key checkpoints, and more.

Can you skip the packaging inspection if the factory says it’s done?

No. You cannot skip packaging inspection, even if the factory says it’s done. Factories often miss small errors during inspection. These errors may include weak boxes or wrong labels. You are responsible for your product quality. If you skip this check, you risk customer complaints.

Some buyers may even return the product or leave bad reviews. This costs money and time. So, if you aren’t physically present, use a third-party quality inspection in China. They can help you catch problems early, before goods are shipped. This one step saves you from big losses later.

Why Quality Inspection for Packaging Is Essential

Packaging checks help protect your product, brand, and profit. Here’s why you can afford to neglect packaging product inspection in China:

1) Protects Product Integrity

Your product goes through long shipping routes. It may move by sea, rail, or through an air freight service from China. It can be dropped or stacked in warehouses. Under all these pressures, bad packaging will likely fail.

You need strong packaging to protect your goods. This keeps the product safe during storage and shipping. So, find a China shipping agent to inspect the packaging before export. During physical absence, it’s the only way to ensure product safety.

2) Prevents Financial Loss

Refund requests and returns are likely results of poor packaging. Things like these can add up quickly. Time, money, and energy are all wasted due to rejected shipments. So, to avoid all of this, just inspect the packaging.

You may be using a global sourcing method or a dropshipping agent. Either way, you still face the same risks. Your company can’t afford to have subpar packaging. So, add quality inspection to your product sourcing strategy. One small step, as this will protect your profits and save your business.

3) Ensures Branding Consistency

Your brand should look the same every time. Labels must be correct, and colours should match your design. A smudged logo can make your product look fake.

If you offer custom packaging, the details matter even more. Check each box before shipping from China. Make sure your logo, font, and design are correct. This keeps your branding sharp and consistent. It builds trust with buyers and keeps your image strong.

4) Improves Buyer Confidence

Buyers notice the box first before seeing the product itself. If the box looks bad, trust drops instantly. A clean, sturdy package demonstrates quality.

A strong box makes the product look more valuable. It also protects it in transit. When using global express shipping services from China, this matters even more. Buyers expect high standards. So, give them packaging that makes your brand shine.

5) Identifies Production Flaws Early

Some items may have missing labels, faulty printing, or flimsy cardboard. These issues will reach the consumer unless you verify. So, you can discover production flaws early with a good package inspection. Catching this early makes it possible to fix before export. This saves time and prevents product returns.

Consider adding this step to your product sourcing service. This allows you to rectify problems. It ensures that your goods remain neat and presentable upon delivery.

Types of Packaging Quality Inspections

Different inspections help catch problems before the product leaves the factory. See the packaging inspection types below:

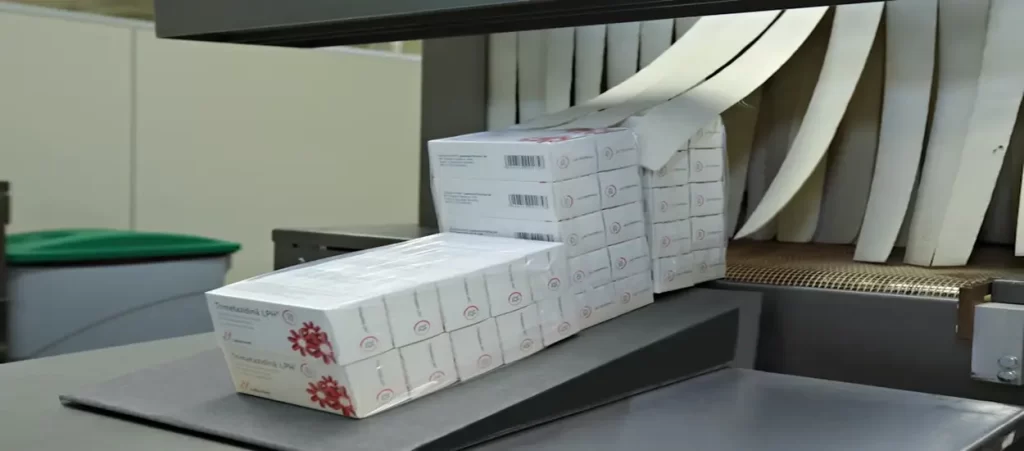

1) In-line Inspection

This check is done while the items are being packed, and it helps find mistakes early on. You can quickly fix anything wrong. It checks if materials meet your sourcing requirements. You also make sure that the right box is used.

This step helps you save time and money. After mass production is over, you no longer have to change anything. It gives you the power to take care of problems before they get worse.

2) Pre-shipment Inspection

This is the last check before shipping from China. It happens after all products are packed. You check out every part of the boxes to ensure they are closed. During this stage, you can confirm if all the labels are correct. You also check for damage or dirt.

This step is vital for quality control in China. It helps you feel safe and have peace of mind before exports.

3) Drop and compression testing

During long trips, packages must stay safe. So, this test checks how strong the boxes are. The box is dropped from different angles. Then it is pressed down to check its strength. You do this to know if it can handle stacking.

Sea shipping from China can be rough. This test shows if the box can survive it. Doing this is very important for the safety of fragile products.

4) Barcode and label verification

Each country has its labelling rules. So, the inspection helps you adhere to them. Ensure the barcode is easy to read and located correctly. Note that the labels need to match what’s inside. Customs may hold up your package if something is wrong.

Conducting barcode and label verification keeps your package from getting stuck in customs. You also get to stay away from fines. Make sure your sourcing agent knows the rules of the country you want to sell to.

5) Visual checks

It’s very simple to do this inspection since you only need to look at the boxes. Check for tears and scratches. Keep the print clean and colours bright. Fix the design right away if it’s not clear.

This step helps keep your custom packaging looking sharp. When importing products from China, it guarantees that your product looks great upon arrival.

Key Standards, Checkpoints & Checklist (Inspired by Our QC Model)

Follow important checks to make sure your packaging meets high standards:

1) Material checks

Check the type of material used in the box. A corrugated board must be strong and should not feel soft or thin. Check the GSM to confirm thickness. Wet boxes break during delivery, so be sure the box is moisture-resistant.

Eco-friendly packaging materials may benefit your brand. This is very important for plastic products sourcing from China. Always test the materials before you buy in bulk.

2) Structural integrity

A good box must be strong and well-built. Look at the sides and seams. When you fold and close the flaps, they shouldn’t break. The box must hold weight without bending and should also fit well on pallets.

Palletisation is a key part of sending goods by sea from China. Boxes that aren’t strong will fall over. Hence, be sure to check the structure before shipping. This helps you stay safe, as a simple mistake can cause a big loss.

3) Surface and finish

The outside of the box must look neat without tears or scratches. Check that all cuts are clean. There should be no extra paper sticking out. No bubbles or glue marks should be on the surface.

Smooth boxes look more professional. Your customer will notice this first. Great finishing makes your product look premium. Buyers trust you more when boxes look clean.

4) Label inspection

Each label must be clear and correct. Check if the barcode is easy to scan. If not, the product may get stuck in customs. Labels should be in the right spot. The font must be readable. Also, check if the barcode matches the item inside.

Good labels help during import from China. You also avoid mistakes in tracking and stock control. Never skip this step before shipment.

5) Internal protection

Boxes are not enough. The products need internal protection, too. A foam, bubble wrap, or cardboard divider helps with internal protection. This keeps items from moving around.

Strong internal protection helps during sea shipping from China. Without it, products can break in transit. It keeps your goods safe for you and the end users.

Best Practices for Ensuring Packaging Compliance

These steps help you avoid delays, damage, or rejections during shipping:

1) Define clear packaging guidelines

Write down clear packaging rules for your supplier. This should include the box type and size. Add exact measurements to guide them. Include pictures if possible, so nothing gets missed. When you source from China, this step is key. It helps suppliers follow your vision.

Make sure the China supplier knows the material type, too. Always go with this strategy to prevent costly mistakes. Clear specifications eliminate problems before they happen. Everyone works faster and better with good packaging guidelines.

2) Check all packaging types

Check more than just the product box itself. Always look at the outside box, too. The product box is what customers see. The outer box protects during shipping. Your items may come broken if one is weak.

When you buy from China, this is a very critical factor. Outside boxes are pushed and handled roughly. So, have a reliable China sourcing agent help you look over both boxes. That way, you won’t miss anything. Before they leave the factory, both boxes must pass your checks.

3) Use Physical Mockups or Prototypes

Before full production, always ask for a sample box. This is called a mockup or prototype. It helps you see if the box fits your product. You also check colours, materials, and design.

A China sourcing company can help with this step. They collect samples and send photos. This saves you from big losses later. If the sample fails, you change it early. Never approve mass production without seeing a sample first.

4) Create a Custom Packaging Checklist

Every product needs a special checklist. Start by listing what matters most. This includes size, barcode, labels, and box type. Also, add rules for the destination country. For example, boxes for air shipping need strong tape.

When importing products from China, this checklist helps everyone stay on track. Share it with your sourcing agent and supplier. They follow it step by step. It reduces packaging errors and other sourcing mistakes when importing from China. Your packaging meets all standards when this list is adhered to.

5) Schedule inspections properly

Timing is very important. Do not wait until the very last second before you decide to inspect. Changes cost more if you check in late. So, set up checks to be done before and after packing.

You can also have your China sourcing service take care of this. Doing a final check verifies all boxes. This prevents delays, damage, and missing shipping dates.

Do inspectors check if the packaging meets airline or courier shipping rules?

Yes, many inspectors check if your packaging meets airline and courier rules. These rules help make sure your goods stay safe during shipping. Inspectors examine weight, size, tape strength, and packaging. Large boxes may be rejected or cost more to ship.

Air cargo requires strong, sturdy packing. Some inspectors run tests that copy real shipping conditions. This lets you see how well your box works. A China sourcing company can help you with this step. They understand local and global shipping rules. They’ll ensure your packaging fits both.

Before you ship, you should always ask for these checks. This helps you save time, money, and trouble with delivery. Strong, rule-friendly packaging is key when you source products from China.

What Happens When You Skip Packaging Checks vs. When You Don’t

Skipping packaging inspections is a shortcut. The cost shows up later. It reflects in your profit margin, brand image, or customer trust.

Here’s how the outcome differs when you skip the check versus when you don’t;

1) Skipped Checks Lead to Invisible Failures

Not all packaging defects are visible at a glance. Some boxes pass a surface look but fail under pressure or poor stacking. Without testing, these flaws go unnoticed until goods reach the buyer, damaged. Always ask for drop or compression testing.

- With Inspection: Even small faults like weak adhesive seams or poor GSM boards are caught. Testing methods mimic real transit conditions. You get to fix issues before shipment, not after a complaint.

2) No Check = No Claim Backup

If your items arrive broken and you skipped packaging QC, there’s no proof of fault. Most Chinese suppliers won’t compensate unless you have pre-shipment inspection records.

- With Inspection: You get a report, photos, and proof. These documents prove your packaging met the required standards. If damage occurs later, this record supports your claim with insurance or suppliers.

3) Brand Trust Suffers Quietly

Your buyers won’t always complain. Sometimes, they may just stop buying. Poor packaging leads to disappointment that isn’t always voiced. Over time, this results in low repeat purchases.

- With Inspection: Packaging reflects care. Neat boxes, clean logos, and undamaged goods! They build customer trust.

4) Returns Multiply When You Skip

One packaging issue can lead to multiple return cases. It happens most during festive seasons or peak shipping times. You spend time handling disputes instead of growing your business.

- With Inspection: Return rates drop. Boxes are tailored to your products. This leads to smoother last-mile delivery. Plus, it gives a better unboxing experience.

5) Skipped Checks = Extra Handling Costs Later

If your forwarder finds poor packaging later, they may re-box or re-label your goods. These extra tasks come with added labour and materials.

- With Inspection: Your goods are ready to ship right from the factory. You avoid unnecessary repacking and time loss.

Do not fall for this – If the product quality is good, packaging doesn’t matter.

Even a high-quality product gets returned if it arrives broken. Many buyers assume that packaging is just a visual touch. However, it is your first line of defence in global trade. Couriers don’t treat boxes gently. Moreover, customs won’t hesitate to reject mislabeled cartons.

At OwlSourcing, we ensure your packaging is as reliable as your product. Our team inspects boxes, barcodes, internal cushioning, and even does drop tests. As a result, your products arrive safe and ready to impress. Don’t risk losses just because “the item itself was fine.”

Read More:

- Top Packaging Manufacturers in China

- Custom Packaging for Amazon FBA

- Quality Inspection for Pet Products in China

- How to Source Die-Cast Components from China?

Final Thoughts!

Packaging is more than just a box. It protects your product and your brand image. If it breaks or fails, you lose money and customers’ trust. That’s why you must follow each packaging inspection step closely. Write clear packaging checklists and always test samples at the right stages.

Be sure to check outer boxes before shipping. Your checklist should match products and shipping methods. Also, schedule inspections early. You may avoid damage and delays with these precautions. Good packaging means safe delivery. Then, safe delivery means happy customers.

Need help with packaging inspections or product sourcing from China? OwlSourcing is your trusted sourcing agent for reliable quality control and safe deliveries. Contact us today. Our team is ready to guide you through every packaging step and protect your profits.