China is a significant player in the world’s machinery production market. Businesses buy from China due to its cost advantage and industrial capacity.

Buying machinery from China is an excellent decision for businesses. So, knowing how to work with China suppliers in the machinery wholesale market is crucial.

This machinery sourcing guide is ideal for buying machinery from China. It covers the advantages of Chinese production and essential considerations for sourcing. It also explains how to discover reliable machinery providers.

By the end, you will understand the processes of sourcing machinery from China.

Key Highlights:

- Am I ready to source machinery from China? Consider the cost advantages and advanced production methods in China sourcing.

- What do I need to know before buying machinery from China? Understand the importance of finding reliable suppliers and negotiating prices with them.

- China offers diverse expertise across industries. It allows businesses to find suppliers who understand their specific needs.

- Successful sourcing from China involves thorough research. Besides, you should also hire a reliable agent to perform the actual sourcing process.

Main Reasons to Prefer China for Machinery Sourcing

Machinery is increasingly sourced from China. Well, it’s easy to understand why companies import from China. The significant price difference attracts businesses. China’s manufacturers have improved production methods to reduce costs without losing quality.

Government subsidies for manufacturing sectors contribute to this cost-effectiveness. Efficient supply networks and large production volumes provide economies of scale.

Notably, China’s production sector covers diverse industries. So, you can find experts for almost any machinery you need. You get to work with Chinese machinery suppliers who understand your business. Furthermore, “Made in China” no longer implies low-tech or quality.

China leads in industrial development in many respects. Chinese companies invest in research and development, creating unique machine-building methods.

Automation and robotics in production are examples of new technologies. These technologies rely on materials science to improve custom products and machine parts. They also include IoT features and ideas for Industry 4.0 in plants.

Because of these changes, China often has the newest machine technology. Firms can stay competitive in their markets this way.

Common Types of Machinery Manufactured in China

The Chinese have always been one step ahead in machinery manufacturing, producing an array of machines that suit varied industrial applications.

Some of the most common kinds of machinery imported from China are as follows:

1. Wheel Loaders

Wheel loaders, commonly utilized on construction and mining sites, have earned a high reputation for their solidity, versatility, and reasonable pricing.

2. CNC Machines

China is the central hub for high-precision CNC machines that are used across industries, from automotive and aerospace to manufacturing.

3. Laser Cutting Machines

From metal fabrication to custom signage, Chinese laser-cutting machines are highly demanded in the global market for their precision and efficiency.

4. Agriculture and Food Production Machines

China manufactures advanced machinery for farming and food processing, including tractors, harvesters, and packaging systems for agriculture and food industries.

5. Roll Forming Machines

Those made in China have applications for use in construction, industries, or the manufacturing of standard profiles needed for roofing or metal sheets of goods.

6. Welding Machines

Various kinds of welders-from simple manual arc welding to highly automatic submerged arc-welding systems-manufactured in China apply in many important industrial fields: automobiles, locomotives, or building ships and boats.

7. Packaging and Printing Machinery

Innovations regarding packaging and printing machinery in China involve labeling systems, carton sealers, and the digital printing press.

Finding Reliable Machinery Suppliers in China

There are many suppliers, and knowing where to seek and how to assess partners is crucial. The following are tips for identifying reliable Chinese machinery manufacturers:

1) Working with Sourcing Agents

Working with a sourcing agent can be very helpful if you have never bought from China. These experts know everything about the Chinese machinery wholesale market. They can help you through the whole process of sourcing machinery from China.

A good agent will help you find a manufacturer in China, discuss prices, and set up factory trips. Also, they can help with quality control for machinery in China. Furthermore, sourcing agents can bridge the gaps in language and culture.

Owlsourcing: Your Trusted Partner for Sourcing Machinery from China

Owlsourcing offers end-to-end support in sourcing machinery from China, even making the process seamless for any newcomer.

As an experienced China sourcing agent, we connect you with trusted manufacturers, negotiate competitive prices, arrange factory visits for transparency, oversee quality control to ensure standards, and bridge language and cultural gaps for smooth communication.

With Owlsourcing, you can source machinery efficiently, cost-effectively, and confidently.

With Owlsourcing, you’ll have the confidence and support needed to source machinery efficiently, cost-effectively, and without unnecessary risks.

Whether you’re new to the process or looking to optimize your current sourcing strategy, Ready to simplify your machinery sourcing process? Contact Owlsourcing today to get started!

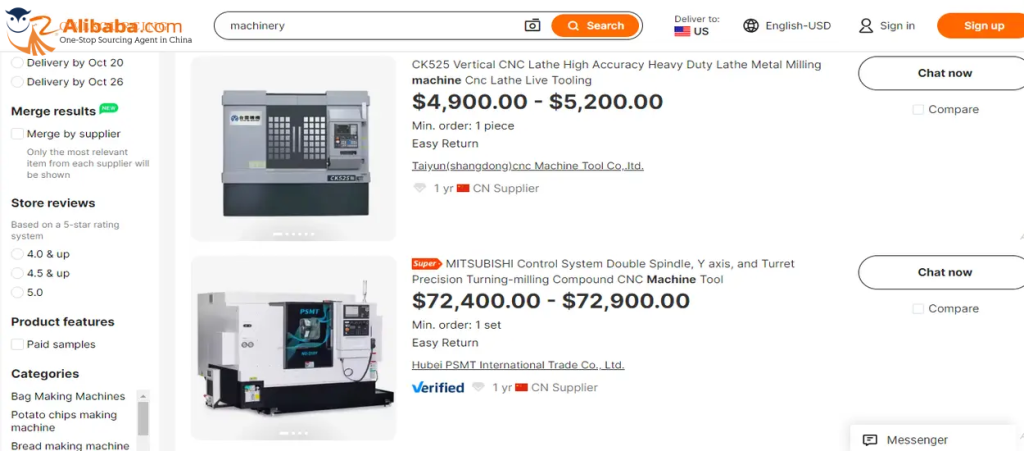

2) Online B2B Platforms

Chinese wholesale websites have changed how businesses connect with Chinese machinery suppliers. These sites are like online shops where people can look at goods and talk to suppliers.

Pay close attention to those with complete business profiles and product details. To get the most out of these sites, use exact search terms for the equipment you need. When sourcing machinery from China, you can contact many sources for quotes.

3) Attending Trade Shows and Exhibitions

Trade fairs in China are venues where Chinese machinery makers can meet. You can check out machinery and discuss specs with suppliers in person. Also, you can get to know them better at these events.

You should know precisely what you want and have questions ready to ask suppliers. Take the time to look at how well the tools are made.

Then, learn as much as possible about your possible suppliers. These networking events can educate you about the Chinese machinery wholesale market.

Key Trade Shows for Buying Machinery from China

| Trade Show | Location | Industry Focus | Benefits for Buyers |

|---|---|---|---|

| Canton Fair (China Import and Export Fair) | Guangzhou | General machinery, industrial equipment, and more. | Assess product quality, connect with diverse suppliers, and explore a wide range of machinery options. |

| Yiwu International Commodities Fair | Yiwu | Small-scale machinery and general industrial goods. | Ideal for buyers seeking smaller machinery or components at competitive prices. |

| East China Import and Export Commodity Fair | Shanghai | General equipment, electronics, and light industrial products. | A broad showcase of machinery categories with an emphasis on export-ready products. |

| Bauma China Exhibition | Shanghai | Construction machinery, building materials equipment, and mining tools. | Focused on heavy-duty and specialized construction equipment, with opportunities to explore the latest technologies. |

| China Electronics Exhibition (Electronica China) | Shanghai and Shenzhen | Electronics and industrial automation machinery. | A hub for high-tech machinery, including automation and electronic manufacturing tools. |

| Beijing International Automotive Exhibition (Auto China) | Beijing | Automotive machinery and vehicle manufacturing equipment. | Tailored for automotive industry buyers, featuring the latest advancements in automotive production technology. |

Why Attend These Trade Shows?

These events offer buyers the opportunity to:

- Directly Assess Product Quality: Inspect machinery firsthand and identify high-quality products.

- Network with Suppliers: Build relationships with manufacturers and sourcing agents.

- Compare Options Efficiently: Evaluate offerings from multiple manufacturers in one convenient location.

Planning to attend a trade show in China? Let us guide you in connecting with the right suppliers and making the most of your visit.

4) Using Industry Associations and Networks

Industry associations and networks can be helpful when looking for Chinese machinery suppliers. Many groups have lists of their confirmed members. These groups often put on events, workshops, and sites.

You can meet other people in your field at these events and get advice. It will help you verify the Chinese supplier’s legitimacy. You can also find and check out possible suppliers through online professional networks.

Getting recommendations from colleagues who have sourced from China can be helpful. Word-of-mouth referrals help you identify the best machinery suppliers in China.

Key Factors to Consider When Buying Machinery from China

Considering a few key factors when buying machines from China is essential. This section of the machinery sourcing guide covers these key factors. Find these essential machinery buying tips in China below:

1) Technical Specifications and Performance

The technical specifications and efficiency of the tools are the most important things. Start by clearly listing your wants and the exact machine’s intended use. Pay close attention to features like power output, capacity, and speed.

Also, check the precision and energy efficiency. Ensure these specs match your production’s needs and the business’s standards.

Many reliable Chinese machinery suppliers offer customization options. Talk to them about how they might be able to change some features to fit your needs better. Set up a display or test run of the equipment to see how well it works for you.

What are the most critical technical specifications for importing machinery?

Understanding the technical specifications of the machinery will enable you to select equipment that meets your operational requirements and also meet local regulations.

I’m a sourcing expert, and this is where paying proper attention to details saves companies from making very costly mistakes.

Many organizations prefer machinery made in factories because it’s easier to access and affordable; even off-the-shelf machinery requires thorough scrutiny.

Here’s what you should focus on:

1. Introduction to the Machine

Begin by evaluating the model of the machine, its purpose, and how it works. Make sure that the equipment you invest in will suit the task at hand. Moreover, knowing the model’s name can help you get spare parts from the store easily if it ever requires servicing or repair.

2. Internal Components

Inside the machine, a deep dive into the internal components will give insight into its quality and how well it performs. Areas to check will include:

- Motors: Long life, efficiency

- Bearings: Strong enough to absorb the demands of your operation

3. Electrical Specifications

Electrical compatibility is important and must be taken seriously when importing internationally. Watch out for:

- Voltage and Frequency: Matching between country power standards

- Power Output: Check energy consumption for unplanned operational costs.

- Efficiency Ratings: The higher the efficiency, the better the savings in the long run.

4. Software Integration

For the machines that depend on software to operate, one needs to know how a system works. Familiarity with operating software guarantees an easy transition in the installation and operation of the system. Ensure it supports your workflow with user-friendly controls.

5. Physical Characteristics

Other physical specifications include weight and dimensions, which influence shipping logistics and costs. In addition, they might tell something about the quality of materials that will make the machine durable.

6. Certifications and Regulatory Compliance

Under the specifications, check for certifications that the machinery meets safety and quality standards. The common certifications include:

- CE Marking: It shows that the machine meets European Union standards.

- ASTM Certification: It means the machine meets American standards in ensuring the safety of materials and products.

- Ingress Protection Ratings: This shows the ratings that reflect resistance to dust, dirt, and water.

Why These Specifications Matter

By carefully looking into these aspects, you are assured that the machinery will be appropriate for your needs, meeting industrial standards and staying out of regulatory problems.

I have always recommended that clients double-check these seemingly minor technical specifications while sourcing any product to avoid risks and ensure better ROI.

Looking for guidance on importing machinery that fits your business needs? Let’s connect and make your sourcing process stress-free.

2) Compliance with International Standards

Make sure that the machinery you buy from China meets all foreign standards. Different countries have different rules about industrial machinery application. Learn about the standards that apply to your area and business.

When doing business with Chinese machinery companies, verify that they follow these standards. You can request proof or applicable certifications.

Avoid suppliers that hesitate to provide this information. Following these requirements makes importing machinery from China permissible. It also guarantees that it is safe and of good quality.

3) After-Sales Service and Support

After-sales servicing may have a big effect on how much your machinery is worth. When you buy something from China, you need to know how the dealer handles service after the sale. Find out if there are extra parts and how to get them.

Get to know how long it usually takes for them to get there. Also, look at how long the guarantee lasts and what it covers.

If the supplier has a partner or service in your country, getting help after the deal may be more accessible. Good service after the sale can cut down on repairs and downtime by a significant amount.

4) Total Cost of Ownership Analysis

When buying Chinese machinery, focusing on the initial price is natural. Consider the machine’s lifetime TCO for a comprehensive picture. This study should look at more than just the initial cost.

Account for shipping and import duties as well as setup and installation costs. Operator training, energy use, regular upkeep, and possible repair costs are also included.

Consider how long the machine is supposed to last and how productive it is compared to other options. You may save money on overtime by making a better choice after a full TCO analysis.

Examples of Machinery Regulations by Country

| Region | Key Regulations | Details |

|---|---|---|

| European Union (EU) | Machinery Directive: Governs all machinery manufactured or imported into the EU. | Importers must comply with the CE Marking Directive, ensuring proper labeling and technical documentation management. ROHS (Restriction of Hazardous Substances) applies to electrical components. |

| CE Marking: Indicates compliance with EU standards. | Ensures machinery meets safety, health, and environmental protection requirements. Some member states may have additional regulations that apply. | |

| ROHS Directive: Restricts hazardous substances in electrical components. | Importers must ensure that machinery complies with this directive to avoid penalties. | |

| United Kingdom (UK) | UKCA Marking: Replaced CE marking after Brexit. | Organizations must follow UKCA requirements to ensure compliance. Non-compliance may result in customs issues, equipment recalls, or seizures. |

| Global | ISO Standards for Machinery: International safety standards developed for various machinery types. | – ISO 12100:2010: Focuses on machinery design, risk assessment, and risk reduction. |

| – ISO 13857:2019: Provides safety distance guidelines to prevent access to hazardous zones. | ||

| – ISO 13854:2019: Specifies minimum gaps to prevent crushing injuries. |

Negotiating Prices and Payment Terms with Chinese Suppliers

Sourcing machinery from China requires careful price and payment negotiations. Successful negotiations with Chinese machinery suppliers improve transactions and relationships. Find tips to negotiate prices below better:

1) Understanding Chinese Business Culture

It’s essential to understand and respect Chinese business culture. Doing this will bring you better deals with Chinese machinery suppliers. China bases a lot of its business relationships on faith and personal ties.

This idea is essential in negotiations. Spend some time contacting Chinese manufacturers before discussing business. Be patient during the bargaining process and show that you value their knowledge.

2) Strategies for Price Negotiation

If you want the best deal on industrial tools from China, you should plan ahead. First, do a lot of study on how much similar machinery costs in the market. When you go into negotiations, this information will help you a lot.

Your target price should be something you’re ready to discuss but don’t mention it too soon. Many Chinese suppliers expect negotiation, so their first price might be flexible. When you talk about price, don’t just talk about cost; talk about value, too.

3) Common Payment Methods and Terms

When buying industrial machines from China, research standard payment options. You must know how to send money to China. Wire transfers, L/Cs, and PayPal are some payment options.

Some suppliers like to see a deposit paid upfront for first-time deals or big sales. The rest of the payment is due before the goods are shipped. It is the best way to pay Chinese suppliers.

Some sellers may offer trade guarantee programs through sites like Alibaba. When you talk about payment terms, be clear about what you want. Voice your concerns and be willing to find a solution that works for both parties.

4) Avoiding Financial Risks in Transactions

Importing machinery from China requires being careful. Before paying for the machine, you might want to use a service that you can trust. The service will hold the money for you until you get the product and check it out.

To protect your own interests, talk to your bank about any letter of credit terms. You might want to hire a third-party quality inspector in China to check out the big machines. Before paying for it in full, they would make sure it meets your needs.

Read More:

- Top Products Imported from China: Exploring Deep

- How To Buy Wholesale From China?

- Top Ways to Find a Reliable Sourcing Agent in China

- Customs Clearance in China

Final Thoughts!

China can be a good place for businesses that want to buy cheap, high-quality tools. This machinery sourcing guide has talked about essential parts of the buying process. You need to find reliable sources, negotiate prices, and lower your risks.

If you know about Chinese business culture, you can make smart choices in business. A close study of technology specs and safety standards is also a good idea.

Remember that good sourcing involves talking to people, doing study, and negotiating. Buying tools from China may have some problems, but it saves money in the long run. It lets you use cutting-edge technology and gives you more ways to make things.

So, contact our team to pick the most affordable China sourcing service plan for you. OwlSourcing will help you at every step of importing products from China.