How to Conduct a China Factory Audit for 100% Ensuring the Quality of Our Goods?

The Shenzhen Gamble: Are Your Chinese Partners a Great Ally or a Risky Challenge? Alright, let’s get real for a

The Shenzhen Gamble: Are Your Chinese Partners a Great Ally or a Risky Challenge? Alright, let’s get real for a

Packaging is not just for looks. It protects the product inside the box. If it isn’t of good quality, your

In this article, we aim to highlight the significance of quality control in China. Let’s start with a common, real-life

As the pet product industry expands, the demand for quality is greater than ever. Whether you are importing toys or

Temu ads are everywhere, from TikTok to YouTube. The e-commerce site has become popular and garnered the trust of thousands

Have you seen an unbelievably cheap gadget on AliExpress? Did you feel like this is too good and inexpensive to

Have you ever launched a product you were truly excited about? It feels great at first, until doubts about its

Are you worried about the quality of the products you import from China? Perhaps you’ve received a shipment that didn’t

When you make or buy products from China, quality control is very important. It helps you make sure your products meet your standards and your customers’ expectations.

Let’s go step by step through how the inspection process works, from the beginning of production to the final shipment.

You can also explore other pages in this category to learn more about the quality control process, the best third-party QC providers, and how to check your product quality before shipping, among other helpful topics.

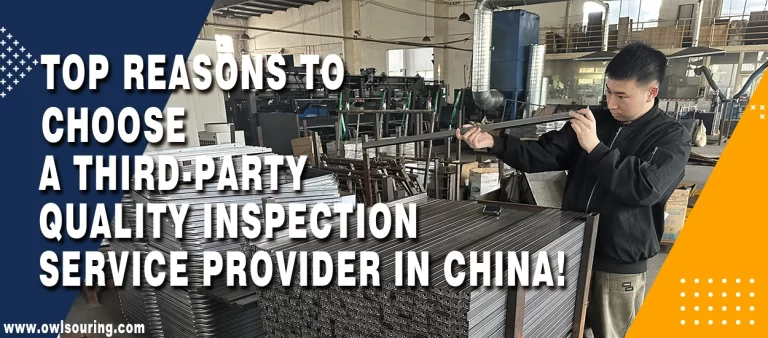

China is one of the biggest manufacturing countries in the world. You can find almost any product there.

However, quality can be very different from one factory to another. Some are excellent, while others may cut corners.

So, to succeed, you need a good sourcing plan and strong quality checks.

Quality control makes sure your products are made the right way. It also checks that they meet international standards before shipping.

In China, factories have different levels of equipment, skills, and management. That’s why inspections are extra important.

First, comes the Pre-Production Inspection (PPI).

This happens before production begins. Inspectors check if the factory is fully ready to make your product correctly.

They look at materials, components, and the production plan.

This early check helps find problems before they become serious. It also ensures the factory has the right people, tools, and systems in place.

Next is the During Production Inspection (DUPRO).

This takes place when around 20–50% of your order is finished.

Inspectors look for quality issues while production is still happening.

If something is wrong, the factory can fix it immediately.

This step keeps production on track and avoids larger problems later on.

After that, we have the Pre-Shipment Inspection (PSI).

This is the final check before products leave the factory.

Inspectors test samples from the finished goods to make sure they meet your standards.

They also check packaging and labels to ensure everything is correct for export.

This step helps you avoid receiving poor-quality or damaged products.

Finally, there’s the Container Loading Supervision (CLS).

This happens when your products are being loaded into containers.

Inspectors make sure the right items and quantities are shipped.

They also confirm everything is packed safely and securely.

This step helps prevent losses, damage, or mix-ups during transport.

It gives you confidence that your shipment will arrive in good condition.

Strong quality control and good supply chain management work together.

By using a trusted third-party inspection company in China, you can keep every step of production under control.

Clear communication, regular checks, and clear standards reduce risks.

In the end, this approach helps you deliver reliable, high-quality products.