Estimated reading time: 11 minutes

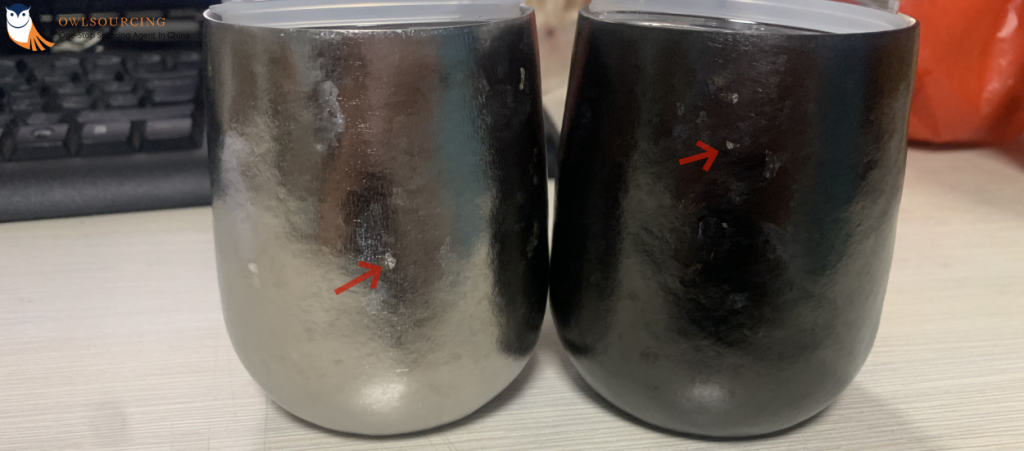

Are you worried about the quality of the products you import from China? Have you ever received a shipment from a Chinese supplier only to find that the final product is nothing like the sample you approved? Unfortunately, this is a common challenge for many importers working in the Chinese market.

If you do not establish quality control-related documentation with Chinese manufacturers before production, you may have bad products. When preparing to source products from China, verifying the Chinese supplier’s legitimacy is important, but quality control ensures that the products you buy from China are of good quality.

Many are concerned about supplier quality control in China. Can Chinese factories produce according to European or US standards and specifications? What are Chinese quality control standards? Additionally, many have shared their experiences of being deceived by product quality in China.

This article provides real solutions to these problems:

- Tired of dealing with costly product defects?

- Struggling to get consistent quality from Chinese suppliers?

- Worried about being deceived by suppliers?

- Is your defect rate hurting your business?

- Not sure who to trust in China?

In this article, we help you find real solutions to quality control in China and provide methods to avoid being deceived by Chinese suppliers. We would also like to inform you about some facts about quality control in China.

Quality Control Services in China

Owlsourcing has offices in China and Hong Kong and offers extensive Quality inspection services in China, chemical and physical testing, and supplier verification in all regions of China.

Our services assist you in sustaining product quality, managing against supply chain risks, and protecting your brand equity.

Get in touch with us today for more details or to schedule your quality inspection service.

How to Arrange Product Inspections in China with Owlsourcing

Ensuring product quality is one of the most important steps in sourcing from China. At Owlsourcing, we make the inspection process straightforward and efficient, helping you safeguard the integrity of your goods before shipment.

Here’s a comprehensive guide on how to arrange a product inspection and the services we offer.

Understanding Inspection Costs

The cost of inspections in China is normally based on a “reasonable price per man-day” basis. This simply means that fees are based on how much time is needed by inspectors to check your products. Every man-day encompasses the following activities, among others:

- Traveling to the factory or inspection site

- Setting up the inspection area

- Random sampling of goods for quality checks

- Performing inspections based on your requirements

- Documentation and reporting

- Traveling back from the inspection site

It depends on the time and complexity required for these steps, all contributing to the overall price to ensure a good, solid inspection.

Note: Travel fees may be incurred for factories that are in remote areas far from metropolitan cities or manufacturing centers.

What You Need to Provide to Arrange an Inspection

Below are the details you have to provide to arrange for a quality inspection with Owlsourcing:

- Supplier Details: Contact information and factory address.

- Product Specifications: Please share the description, photos, and videos where possible.

- Packaging Details: Specify how the products will be packed and labeled.

- Quality Standards: The acceptable and unacceptable need to be clearly stated.

- Variations of Products: In case there are models, sizes, or colors of the product, state.

- Physical Samples: If available, this helps ensure precision at the time of inspection.

Our team will handle coordination and ensure the inspection aligns with your standards.

Types of Inspections We Offer

Owlsourcing offers a whole suite of inspection services at every stage of production for your needs:

- Factory Audit– The supplier’s capability, performance, and compliance can be reviewed.

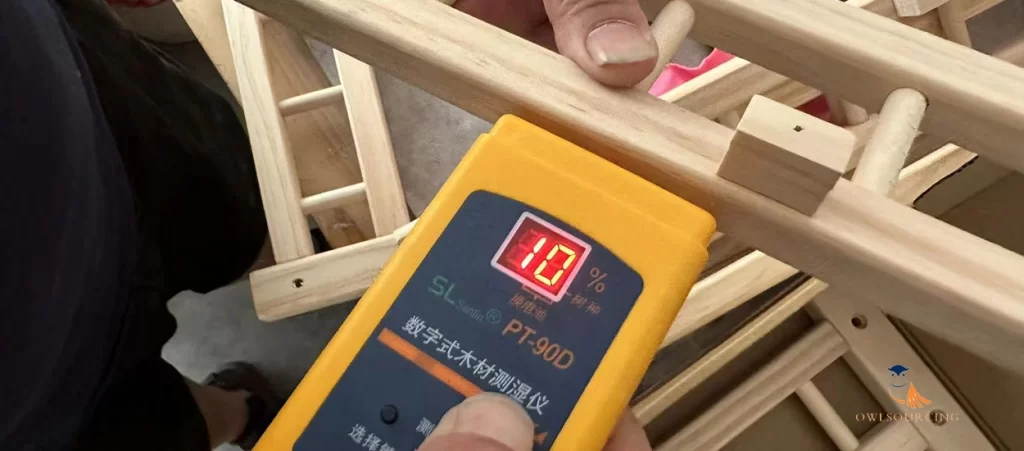

- Pre-Production Inspection– Raw materials and initial production processes can be verified.

- During Production Inspection– Quality can be controlled in manufacturing.

- Pre-Shipment Inspection– The final product can be checked for compliance with your specifications before shipping.

- Container Loading Inspection– The accurate packing and loading of goods can be verified.

- Piece-by-Piece Inspection– A highly detailed check for high-value or critical goods.

Why Quality Inspections Are Important in China?

Low labor costs and economies of scale attract increasing companies to import products from China.

However, do not overlook quality control in China. Attracting customers requires more than just low prices; consumers also consider the quality of products when buying.

If your products lack quality, you will receive numerous negative reviews, significantly impacting your brand reputation.

Chinese-made goods mostly suck because many Chinese business people have lousy business values. When a Chinese manufacturer takes a contract, they often feel little or no actual obligation to manufacture according to spec, if cutting corners will make more money for them or their guanxi network of family and friends.

From: CBS News

We can see that many consumers have a strong aversion to defective products. On a certain level, effective quality control can reduce the risk of product failures.

Note: Prevention before the occurrence of a problem is much more important than rectification after a mistake has occurred.

Inspections save you from risks and guarantee the quality of your products. If you do not inspect, here are some problems you could run into:

- Unexpected shipment delays due to latent quality issues.

- Customer dissatisfaction from receiving defective or wrong products.

- Additional costs associated with returns or replacements.

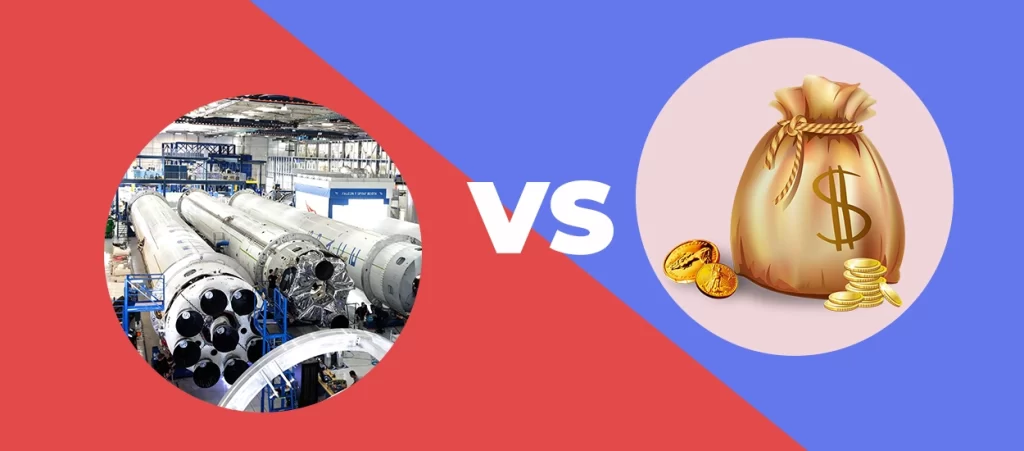

Let me calculate the costs for you in two scenarios.

The first scenario is without quality control, ultimately leading to major quality issues and product recalls.

The second scenario involves effective quality control, resulting in customers being very satisfied with the product quality.

1. Without quality control leading to product recall,

- Recalling products necessitates paying for the shipping costs associated with returning or replacing the products.

- Due to the negative social impact created, you might also need to pay compensation to consumers or partners.

- The greatest impact is the damage to your company’s brand. This can lead to consumers being reluctant to trust you again. Your brand might be labeled as synonymous with poor-quality products, a truly distressing situation.

- Some products might even violate legal regulations, incurring fines.

- In terms of your costs, you’re not only paying double for shipping but also losing in terms of time, which all amount to significant losses for you.

2. Done quality control and customer satisfaction,

- Although investing in human resources, equipment, and some funds for quality inspection, these costs are not excessively high. If you choose Owlsourcing to assist you in sourcing products from China, quality control is one of the basic services we offer. Of course, it’s free.

- You can continuously improve your product based on the feedback from quality control.

- With excellent product quality, more and more consumers will be willing to buy your brand. This not only brings you long-term revenue but also enhances your brand’s recognition.

- Preventing potential product issues reduces the likelihood of future repairs and warranties for that product.

- The products you purchase from China boast the advantages of low cost and high quality, all of which enhance the market competitiveness of your products.

In short, while the first scenario saves a small amount of money in quality control, it incurs substantial costs during the sales stage to rectify these errors.

However, some mistakes cannot be compensated with money.

In the second scenario, ensuring product quality through quality control in China leads to better market reputation and greater customer satisfaction, thereby attracting more customers.

What a great result!

Partner with Owlsourcing to check the quality of your products before they leave the factory.

Flexible Solution for Budget Constraints

If your budget is limited, we recommend the following options:

- Request detailed photos and videos of the production process from your supplier.

- Obtain production samples for review.

- Consider working with reliable wholesalers who pre-screen products.

- These options can help mitigate risks while keeping costs manageable.

Building Long-Term Solutions

Owlsourcing believes in fostering long-term improvements for your supply chain. Our approach includes:

- Full Inspections Initially: Identify common defects and address root causes.

- Advising Manufacturers: Help suppliers improve processes to reduce defects.

- Moving to Random Inspections: Gradually decrease the intensity of inspections as quality improves.

This approach decreases costs over time while ensuring that products meet standards.

Other Services We Provide

To complement your sourcing requirements, Owlsourcing provides:

- Lab Testing: Comply with international standards including RoHS, REACH, and CPSIA.

- Supplier Audits: Assess a supplier’s capability, ethical practices, and facility safety.

- Production Monitoring: Follow up on the manufacturing process.

- Consulting Services: Offer advice in quality control and supply chain management.

Why Owlsourcing?

Owlsourcing boasts of quality and transparency, among other things:

- Local Expertise: Full-time, local inspectors knowledgeable about manufacturing practices in China.

- No Hidden Costs: Completely transparent pricing no-extra cost for travel or weekend inspections.

- Fast Reporting: In-depth inspection reports are available within 24 hours.

From our comprehensive quality assurance services, Owlsourcing guarantees that your products meet the highest standards. Allow us to take care of all your inspection complexities while you invest your time in business development.

For more information or to book your quality inspection, contact us today.

How to do Effective Quality Control in China?

Are you worried about receiving poor-quality products from Chinese suppliers?

Have you implemented quality control but still received products of subpar quality?

Maybe you haven’t found the right approach. In this section, we provide you with a step-by-step guide on how to conduct quality control in China effectively.

Step 1: Understand Your Product Specifications

Clearly define your product requirements and specifications. This includes materials, dimensions, function, appearance, and packaging. Communicate accurate product data to your suppliers.

Step 2: Select a Reputable Manufacturer

Conduct thorough research to choose a reliable manufacturer. Look for manufacturers with a good track record, positive reviews, and experience in your product category. For further information, read this article: Find a Manufacturer in China.

Step 3: Request samples

Before mass production, ask for pre-production samples to verify that the product meets your specifications. If you are unable to confirm whether to collaborate with a particular supplier, you may also consider buying product samples from China.

Step 4: Lab Testing

Lab testing may be necessary for certain products, particularly those with safety or regulatory requirements such as electronics, cosmetics, and toys, to ensure compliance with international standards.

Step 5: Visit Factory

Visiting the factory allows you to directly observe the manufacturing processes, work environment, and the company’s capabilities.

China factory inspection services

For your products to be shipped to the market, you need our China factory inspection services to provide you with quality input.

the expert team of Owlsourcing conducts thorough on-site inspections, where we assess your production processes, the material used, and compliance with your specifications.

We assist you in avoiding costly defects and ensuring timely deliveries.

Step 6: Pre-shipment Inspection

This inspection is conducted when 100% of the shipment quantity is complete and at least 80% is packed. It ensures that the final products meet your specifications and quality standards.

Use a statistically valid method for selecting a random sample of products from the batch to inspect. If any issues are found, they should be addressed before the shipment leaves the factory.

Step 7: Continuous Improvement

After each production run, review the process and identify areas for improvement. Work with your supplier to implement these changes.

Step 8: Reach Out to Owlsourcing

Consider involving independent third-party inspection companies with expertise in conducting thorough and impartial inspections on your behalf.

Owlsourcing is a global sourcing agent. We assist clients in sourcing products from China and manage product quality control to ensure that these products meet our client’s quality requirements.

Step 9: Build a Long-term Relationship

Purchasing goods from a supplier for many years means that the supplier is originally aware of your quality expectations.

Advanced Quality Control Strategies for China Manufacturing

1. Conduct In-Depth Factory Audits

The audit must be conducted before entering into a partnership agreement with a manufacturer. It is not about reviewing certificates and documents; it is about evaluating the capacity of the factory. Focus areas include:

- Supplier background and production history

- Superior Minutes – management’s commitment to quality control

- Systems for handling and controlling quality check checks from the outside (IQC) and within (OQC).

- Organizational programs with worker training and general company operation optimizations.

- Equipment maintenance and production capacity

- Social and environmental reckoning

Audit is very effective since it covers all areas that you might consider to pose a risk to your products and above all it is Effective since it can enable you to determine if the factory is capable of producing products that meet your expectations.

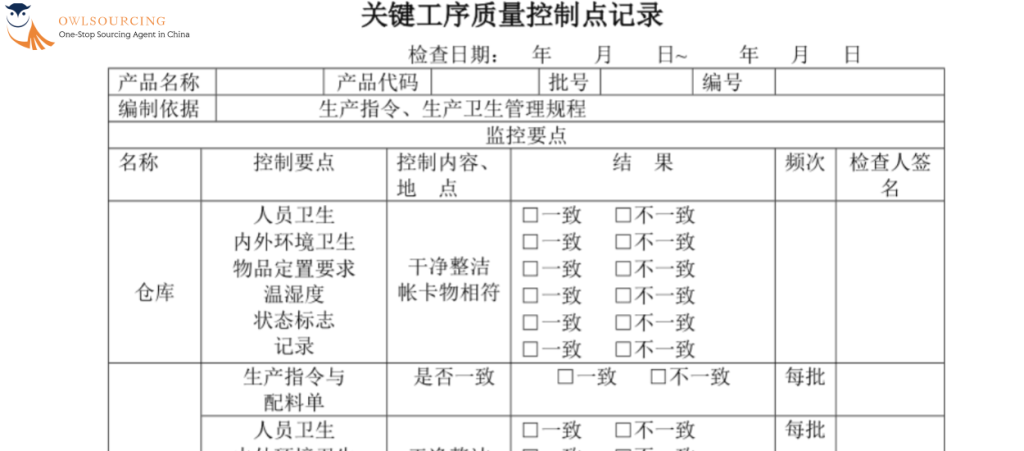

2. Develop a Detailed Quality Control Plan

The next step in your manufacturing process is to establish quality control when you have selected a manufacturing partner. This plan should outline product standards, checkpoints, and test procedures to be employed. Ensure that the plan includes:

- Quality control of various materials and performance analysis

- Regular in-process inspections to catch issues early

- Use of standardized testing methods, such as AQL (Acceptance Quality Limit) for large orders

While at OwlSourcing, we ensure that every product developed meets the set quality standard from the production process by having a specific quality checklist for every product.

3. Implement In-Process Quality Control (IPQC)

Early detection is key to avoiding defects. One can be able to have a look into the quality checks that are performed during the process of manufacturing, and complications are sorted out accordingly. IPQC offers:

- Reduced waste and fewer rejected shipments

- Quicker correction of the quality deviations

- Consistent product output

IPQC is essential if the organization wants to be able to regulate the manufacturing process and achieve optimum results as far as the final inspection is concerned.

4. Perform Final Product Inspections (FPI)

Production is followed by an extensive final inspection, which confirms all requirements that have been defined beforehand. This should involve:

- Functional and aesthetic checks

- Packaging inspections to ensure goods are ready for shipping

- Customized sampling techniques (such as AQL) for larger orders

If any issues are found, the manufacturer must address them immediately. At OwlSourcing the potential of mistakes is completely excluded as clients are consulted to develop clear inspection requirements.

5. Create a Feedback and Continuous Improvement Loop

Quality management is not the end with the products once they are out of the factory. Creating a system for gathering customer feedback allows companies to:

- Define quality problem areas as they persist

- Seeking innovations in those areas either in products or just in production methodologies.

- Improve the overall existing and potential partnerships with suppliers

When it is practiced, every future production cycle is improved on the previous one thus lowering long-run variance.

Expert Advice for China Manufacturing Success

Customize Your QC Approach Based on Product Type

Different Kinds of Products Should Be Handled Differently, It also means that each product has its own approach to Quality assurance in China. For example:

- Mass-Produced Items: The general tests and random checks have the advantage of yielding standardized findings.

- Custom or High-Precision Products: That is why elaborate checkouts, a review of the prototypes at the initial phases of the work, should be made to exclude extra costs for rectifications.

Leverage Local Expertise

Working with a sourcing agent from a third party like OwlSourcing means that the quality assurance standards are set both following what you would expect from Western countries and within the constraints of manufacturing in China.

What Are the Quality Standards and Certifications in China?

It may be noted also that quality standards and certifications in China are in some way dissimilar to those in other parts of the world. Below is an overview of quality standards and certifications in China:

A) GB Standards: Typically, GB Standards regulate numerous products, services, and processes in manufacturing and sectors such as electronics, automotive industries, machines, environment protection, construction, and so on. It is the Office of Standardization Inspection and Quality Technical Committee in China that is issued and framed as the basis for regulation and quality assessment in China. Conformity to the given standards may be mandatory for products manufactured and sold in China.

B) CCC Certification: The recognition gives confidence that these products conform to safety quality and environmental requirements as set by Chinese authorities. It is targeted towards shielding the consumers and the national security.

This process involves product testing or checking any facility, as well as factory inspection and adherence to China’s quality standards.

C) HACCP: HACCP is short for Hazard Analysis and Critical Control Point, which is a scientific preventive tool widely accepted by the international community and applied in China.

Although HACCP is widely used, it has special applicability for the food industry. It merely covers a systematic view of recognizing, assessing, and monitoring risks that are pertinent to food safety.

HAACP aids in controlling hazards anywhere in the food chain; at the stages of raw material reception, production, processing, storage, distribution, and utilization.

D) CQC Mark Certification: Chinese-speaking users will understand the CQC Mark Certification in China as a certification from the China Quality Certification Center.

Despite being in its developmental stage, it plays a significant role in China’s quality standard system more so for consumer products. By and large, the CQC Mark Certification is not mandatory.

E) Environment Labeling Certification: China Environmental Label or Environment Labeling Certification is one of the important certification schemes in China, which is used to label products and services as environment-friendly.

Firms’ products can only earn the certification if they have met certain requirements that have been laid down.

They usually comprise aspects such as energy conservation, minimizing pollution, the emission of toxic substances, corporate management, and responsible utilization of resources.

F) CNAS Accreditation: CNAS Accreditation means accreditation offered to the organization by the China National Accreditation Service for Conformity Assessment.

CNAS currently accredits the testing and calibration laboratories, medical laboratories, inspection bodies, and certification bodies of management systems and products, including ISO 9001 and ISO 14001.

What it means is that whenever a business person or a consumer is using a product or a service that has been certified by a body accredited by CNAS, they are confident that such service meets the standards as set.

Tip: Does China use ISO standards?

Not all Chinese suppliers use ISO. However, the Standardization Administration of China is a member of the ISO and actively participates in international standardization activities.

In China, ISO standards are often adopted as national standards (referred to as GB standards), sometimes with modifications to adapt them to specific domestic requirements.

Some Facts About Quality Control in China

Quality is Directly Proportional to Production Cost

- Higher Costs, Higher Quality: In general, like many manufacturing regions of the world, China saw its cost of production correlating with quality; the higher the cost, the higher the quality. This is because improved quality of materials, human skill, better technologies, and adherence to high standard quality control usually go hand with high cost.

- Cost-Benefit Analysis: This is where issues of costs and quality need to be well aligned toward the achievement of production goals. Low quality can also result from low costs since it will not be able to meet market standards of quality or the customer’s expectation.

Quality control in China requires documentation to set standards

- Essential Documentation: Thorough records are the key principles in managing quality in China. These include Product Requirements, Quality Characteristics, Inspection Acceptance Criteria, and Process Control Requirements.

- Communication Tool: They are written and used by foreign buyers and Chinese manufacturers as a means of passing information about the expected quality and standard.

- Legal Protection: In case of some complication of rows or non-compliance, clear established documentation can be legally defended as well as serve as the remedy that hard be gained.

Cultural differences in quality control in China

- Different Perceptions: There may be different perceptions of what constitutes ‘quality’ between Western buyers and Chinese manufacturers. What a foreign company considers a defect might be acceptable in the Chinese market.

- Communication Style: The Chinese business culture often places a high value on harmony and indirect communication. Direct criticism or confrontation over quality issues might be counterproductive.

- Relationships Matter: Building a good relationship with Trusted Chinese Suppliers is crucial. It’s often through these relationships that better understanding and improvements in quality are achieved.

- Adaptation and Training: Foreign businesses may need to adapt their quality control processes and provide extra training to align with the local manufacturing environment and practices.

Key Insights on Outsourcing to China:

Balancing Cost and Quality

While outsourcing production to China has its benefits and cost advantages, it does not without doubt bring challenges, it is far from easy, and one of the hardest things to deal with is quality control.

Most Western firms are reluctant to execute it because they assume that lower costs translate into negative impacts on product quality.

However, when managed effectively, Chinese manufacturers can deliver exceptional quality that meets or even exceeds Western expectations.

About ‘Made in China’

The perception that everything that is produced in China equates to low-quality products is outdated. Chinese manufacturers are already preparing to make premium goods for the Chinese and international markets.

Firms such as Xiaomi, Lenovo, and Haier are evidence of the new direction forcing change as the Chinese firms exhibit the capacity to produce high quality to meet the Western consumers.

The appearance of China’s middle class has also led to the demand, raising local manufacturing quality.

Understanding Cultural Perceptions of Quality

The degree of working-class preference represents one of the primary obstacles for Western buyers: the differing standards of quality assessment.

There is a way for the Chinese manufacturer to be more relaxed about quality—what the Western buyer would consider a flaw, the Chinese manufacturer will consider as acceptable.

For example, color and size may differ slightly and are generally acceptable because of this. The essence of the gap is in effective information exchange, an unambiguous definition of quality parameters, and shared expectations.

Paper Audits vs. Real-World Quality

Audits following the Western bad practices could sometimes be misleading.

A factory may look disorganized and may not show concern for paperwork and formal procedures, but it could manufacture good products.

On the opposite, there are those manufacturers who may pose an excellent image on paper but flop when they are on the field.

It was also noticed that ‘real’ quality control could not be purchased; it was best supplied by those with experience and a strong understanding of the Chinese manufacturing processes.

Experience Over Paperwork

Much like the Japan of the 1960s, many of China’s smaller factories still source their quality standards from their employees, excluding any official quality assurance procedures.

These workers have years of experience coupled with good vision and can identify certain problems that a more regular computerized system may not see.

All this practical knowledge is very useful and, therefore, businesses should not underestimate the importance of a skilled workforce in choosing their manufacturing partners.

Selecting the right Manufacturer

The main idea in China sourcing is to identify a factory that understands your product line and has implemented its products in Western countries.

These factories are more likely to appreciate the quality standards which need to be met.

There must be strong communication—there should be little room for ambiguity, and specificities must not be hidden; inspections should be carried out by a third-party QC team or directly by the buyer. Companies, that have no objection to such inspections, are typically more honest.

Read More,

- How To Import Bags From China: A Detailed Guide

- How to Verify Chinese Supplier’s Legitimacy: 8 Ways to Solve

- What is a Sourcing Agent and What Does a Sourcing Agent Do?

- Buying Product Samples from China: Your Ultimate Guide

- Amazon FBA Sourcing Agent in China: Ultimate Guide

Final Thoughts

Preventing and providing Quality control in China is a crucial matter to import products from China.

For this reason, it is recommended that one works with a sourcing agent from China who is well-informed on Chinese laws.

Here to note also is the fact that we can assist you to reduce on so many issues that may arise during procurement.

2 thoughts on “Quality Control Company in China & China Product Inspection”

common challenges in quality control include cultural differences, logistical issues, and varying quality standards.

Hello Mark,

The challenges you mentioned are indeed very important aspects in the field of quality control. Cultural differences, logistics issues and different quality standards are all issues that need to be carefully considered and resolved in our pursuit of high-quality services and products. If you need help, you can send us an email and we will be happy to help you.

Also thank you for your insights, this is a great inspiration and learning opportunity for all of us.