Don't have time to read the whole guide right now?

No worries. Let me send you a copy so you can read it when it’s convenient for you. Just let me know where to send it (take 5 seconds):

I received a phone call from one of my Chinese vendors, and he asked me, “What would be your comments on the sustainable material business?”

My answer is positive. Why? We will drive more in-depth into this topic, and then you can find the answer. You will also find out how to find high-potential sustainable and biodegradable materials/products from China for your business.

The reputable plastic toy company LEGO Group has been researching sustainable and biodegradable plastic to replace traditional oil plastic for several years, and recently they announced that they had achieved something through their continuous effort.

Lego has invested $155 million into its sustainable materials center since 2015. Over 100 employees are working to use sustainable materials to replace their plastic bricks by 2030. The company recently showcased its new bricks made from plant-extracted materials towards the end of last year. source.

There are a total of twenty-five different shapes of Lego bricks along with various accessories that are also produced by plant-extraction materials: sugarcane-based polyethylene. The sugarcane-based polyethylene is one kind of sustainable and biodegradable plastic. It’s an important milestone for the group and creates a significant impact on the sustainability environment development.

What is sustainable and biodegradable material? Are those materials existing in the wholesale market?

Table of Contents

ToggleWhat does sustainable material and biodegradable material mean?

Sustainable Material

Sustainable material means the article, which can cause a limited negative impact on the environment and people during its raw material extraction, energy, or practice. Usually, sustainable material consists of three significant features, which are natural genes, harmless, and renewable capability.

Seeking sustainability for the environment is a common topic and priority for all the countries in the world. We can call materials such as Bamboo, wool, bee wax, coconut, and other plant-extraction-based materials sustainable material.

Sustainable green building materials like wood, sand, clay, stone, and cork are also widely used today all over the world.

Those green materials generate nature sustainability.

Let’s have an example of “Bamboo” material, which is a “STAR” to achieve an eco-friendly environment.

The Bamboo is the fastest-growing plant on the planet (around 3-5 years, renewable material). The Bamboo raw material (natural and not synthetic material) is recyclable, biodegradable, and harmless to sustainability environment development. It removes carbon dioxide more than the trees and meanwhile produces 35% more oxygen.

Biodegradable Material and Nonbiodegradable Material

Firstly, let’s define the non-biodegradable material. What does nonbiodegradable content mean? Let’s have an example of the “Plastic.” Why is plastic not biodegradable? The raw plastic material is extracted from crude oil and takes centuries to break down due to the use of long-chain molecules.

The long period of material breaking down is harmful to the sustainability of the environment. That’s the reason why scientists and chemists are creating biodegradable materials to release the terrible results caused by non-biodegradable materials.

We would define the biodegradable material as the one that can be broken down quickly in a workable time by natural processes. Products are usually broken down by bacteria, fungi, or other simple organisms. By this definition, most chemicals are biodegradable; the only thing differing would be the amount of time it takes to break down its material.

A piece of bread will break down rather quickly, whereas a piece of plastic will take decades and beyond. The ideal final products of any complex product of Carbon, Hydrogen, and Oxygen would be Carbon Dioxide(CO2) and Water (H2O).

A majority of products are made mostly of these three elements. The previously mentioned piece of bread is made mainly of these, and after breaking down, it will eventually degrade to CO2 and H2O.

This process would be accelerated if we ate the bread, and our body would break it down and use it as energy until only CO2 and H2O were left.

Why Use Sustainable And Biodegradable Plastic Material? The World Pollution

What pops up in your mind when you see the above image? Pollution is the top enemy of the sustainable living.

Do you know that millions of tons of plastic end up in the ocean every year? We are on course to have more plastic than fish in the sea by 2050!

The world governments are emphasizing and implementing a sustainable and green environment development strategy. Businessmen with sensitive acumen are following the wind and changing their plans.

Lou, who is the founder of the Yiwu Soton Daily Nessicity Co., Ltd (the world’s largest plastic straw manufacturer), decided to invest more than US$ 15 million to double the facility size in Yiwu, China. The reason why he made such an important decision is the optimism of the future of biodegradable straws with sustainable material.

The new production line is for producing biodegradable straws made from polylactide acid( PLA). PLA is a type of biodegradable plastic raw material. Both the government’s sustainability strategy and the feedback from the customers made Lou believe that biodegradable straws represent the future.

Just like what Lou did to his business, more Chinese plastic manufacturers are switching and using corn, sugarcane, and other crops to develop biodegradable plastics. That’s a positive signal to the world as the plastic factories in China are responsible for almost 30 percent of the global plastic industry.

So why using sustainable and biodegradable materials will be a trend in 2024?

1. We need to protect the planet we own together.

2. More and more businesses are switching to sustainable business and using biodegradable materials for their business.

3. It follows the UN sustainable development goals

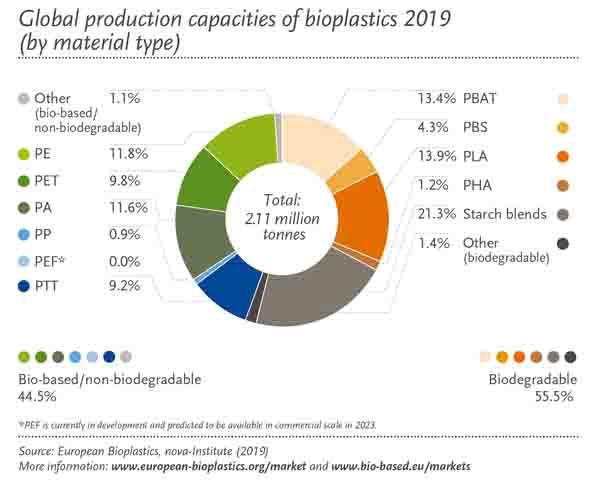

Global bioplastics production capacity is set to increase from around 2.11 million tonnes in 2019 to approximately 2.43 million tonnes in 2024. source.

Biodegradable plastics altogether, including PLA, PHA, starch blends, and others, account for over 55.5 percent (over 1 million tonnes) of the global bioplastics production capacities. The production of biodegradable plastics is expected to increase to 1,33 million in 2024, mainly due to PHA’s significant growth rates.

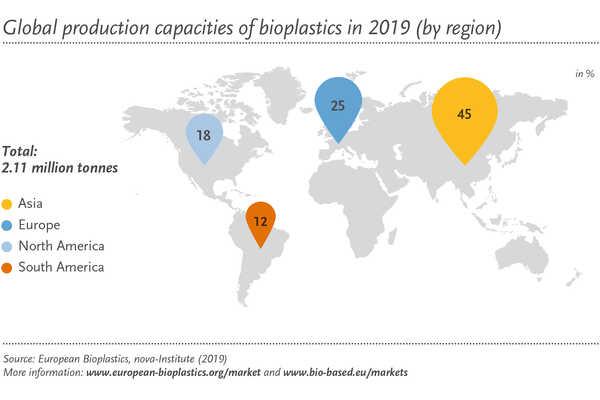

The bioplastic global production capacity in 2019 (by Regions)

China, as the world factory is moving its steps toward a more “green” future and sustainable development. For instance, the production capacity of the polylactide acid(PLA), is quickly raised from a small base. Chinese factories have been importing PLA directly from the USA in the past few days, but now the percentage is going down.

It’s no doubt that you should know how to import sustainable and biodegradable materials/products from China! As you can see from the above status image 45% of global bioplastic production capacity is generated in Asia regions, China, for the most.

What are the accessible sustainable and biodegradable raw materials in China’s wholesale market?

Status shows us that we should be aware of the growth that is happening in the sustainable and biodegradable product market.

Let’s explore what’s the existing high-potential materials in the open market.

Polyethene made from sugarcane

Polyethylene is produced from ethylene derived from sugarcane ethanol. It has the same properties as traditional polyethylene. It is 100% recyclable and biodegradable. It also has precisely the same durability, quality, and safety as we have today(traditional polyethylene). You never notice the difference between oil-based plastic and plastic made from sugarcane ethanol. “More and more people are getting concerned about it,” says Tim Brooks, the Lego vice president who heads up environmental responsibility efforts.

This is a sustainable and 100% recyclable material that represents eco-innovation at its finest! The production of 1kg of sugarcane plastic prevents the release of 4.6kg of carbon dioxide entering the environment.

Current Status: Will need to finish engineering plans for facilities that will convert that ethanol into hundreds of thousands of metric tons of polyethylene, the world’s most widely used plastic. It is the trend of the world, and we will make it work although it takes some time.

PLA (Polylactic acid) Cornstarch as the primary material

The cornstarch-based PLA is the top sustainable and biodegradable material for the future plastic industry.

Polylactic Acid (PLA) is a new degradable plastic. It is the first viable thermoplastic that is produced from a plant-based feedstock and processed by conventional melt processing technologies.

It is used in biomedical applications for bottle production and compostable food packaging. Mass production has tremendously reduced the cost of PLA production. The current market situation for PLA and biodegradable polymers is described as well as applications across a range of market sectors, and the mechanical, chemical, thermal, rheology, and degradation properties of PLA.

Current Status: Chinese manufacturers are importing PLA raw materials from the US; the supplying capacity is not stable, and also the price changes frequently. It causes the PLA products to be more expensive than the typical plastic products. But right now the Chinese domestic production capacity of the PLA is improving so the situation will change a lot in the future.

We will wait and see what will be the production capacity of PLA in China and the cost.

Bamboo pulp paper/material

Bamboo products are getting more popular. But why choose Bamboo?

- the short growing cycle of 2-5 years, while the woods took at least 5-10 years

- Compared with trees: bring more oxygen and remove more carbon dioxide

- Low-cost and easy-to-plant

- sustainable, biodegradable, and recyclable material

People in the UK are particularly aware of how to benefit by using bamboo material products, especially for biodegradable packaging and in the commodity consumption area.

They are using more bamboo products than wood products in daily life, such as bamboo paper cups, bamboo paper straws, bamboo facial and body wipes, bamboo facial tissues, bamboo paper bags, bamboo napkins, and bamboo hand towels.

You can easily find the packaging you received made with bamboo materials.

It comes up to the next question: Do you know where to find and import sustainable and biodegradable materials or products from China?

Wheat Straw Material

The Wheat Straw refers to the stem and leaves left after the harvest of crops. It is usually used as fuel, feed, and fertilizer to achieve sustainable agricultural development. It contains fiber, also used in paper and furniture materials.

The wheat straw material is the popular eco-friendly material used for tablewares such as spoons and plates.

There is still a long way for the material to reach the 100% pure wheat straw material product as currently it still needs to mix with the raw material of crude oil and other additives to stabilize its chemical properties.

But there’s no doubt that wheat straw material is on the way to being the “superstar” in the world of sustainable and biodegradable material.

You can find wheat straw material in the south of China, especially in Dongguan City, Guangdong Province.

How to Source Sustainable and Biodegradable Products for Your Online Store?

Is there an existing biodegradable materials list? It’s not easy to find the complete list, but we can list sustainable and biodegradable products with high potential for your online business.

The eco-friendly and environmental protection material products are more and more popular on E-commerce sites like Amazon.

In the Chinese wholesale market, you will find plenty of manufacturers producing and supplying biodegradable products.

Bamboo fiber products

Products made of bamboo material are always considered typical sustainable products.

Most of them are food packaging, containers, bamboo hot food boxes, paper straws, bamboo Pizza boxes, hamburger boxes, and so on.

I suppose the first question that pops into your head would be, “Is it safe”? The answer is positive, according to the testing result, the final products can meet the FDA standards. The bamboo fiber products are surely safe for the environment and 100% bio-degradable.

You can navigate the resource region as we mentioned in the previous post about how to find the right vendor, click here for more details.

Where are the most abundant bamboo resource regions in China? It is the Sichuan Province. Yes, I guess you know that’s Panda’s paradise as well. Sichuan is the China Bamboo base and also the manufacturing base for bamboo pulp paper.

The largest bamboo fiber manufacturers are based in Sichuan.

PLA (Cornstarch)

PLA materials are kind of stuff made from plants and are being used for packaging and food containers mostly, such as PLA bags, cup lids, and food boxes. It’s safer than traditional plastic, and it broke down within 60~90 days.

Currently, the US is the most significant origin of PLA raw material and can provide 70 thousand tons every year. China is chasing with a capacity of 5 thousand tons every year. For sure, China will be a comparable supplier of PLA in the future.

Sugarcane biodegradable products:

Taiwan has abundant resources of sugarcane and is well established for its sugar cane bioplastic industry. Products like sugarcane straw are sold all over the world and have a good reputation for their high quality. So you can navigate the Taiwan market if you want to drive more in-depth with sugarcane bioplastic products.

The Advantages and Disadvantages of the Biodegradable Material

Advantages:

- Biodegradable: It can be 100% broken down into parts over time by the action of biological organisms and processes.

- Sustainable: Traditional plastic made from oil can hardly renew. Biodegradable material is made from plants, such as sugarcane, corn starch, and Bamboo which are renewable materials.

- The material doesn’t cause dangerous chemical leachate that can poison water or off-gassing that can pollute the air. It means the substances are not harmful to the environment.

Disadvantages:

- Cost: The biodegradable materials are more expensive than traditional or ordinary materials. The cost would be lower after the upgrade of the production capacity.

2. Time: Finding the perfect oil-plastic alternative material is still on its way. It’s due to the new sustainable/biodegradable material’s production capacity and relatively high cost for small to medium-sized businesses.

But we never forget the ultimate target is to use specific materials to replicate the existing oil plastic in the future.

How about the Status of Recycled materials?

More and more large retailers are asking their vendors to use recycled material for producing their orders. They could lower their purchasing cost by using recycled material.

So what are the trends and current status of recycled material? Is it safe and meet the related testing requirements, especially for international trading? We will share more about the current status of the recycled material market in the Chinese domestic market.

Let’s take the PVC plastic as an example.

In the Chinese domestic market, many vendors can provide recycled PVC material. What’s your first concern when using recycled PVC plastic for your business?

It may relate to material stability, and testing performance, which includes chemical and mechanical testing.

Indeed, we have tested the recycled PVC and below conclusion for your reference:

Chemical: We found that the color pigments may sometimes fail in Organotin requirements even when we use fresh material. In using recycled PVC, we would never know what is mixed in it. It can hardly pass EN71 testing standards, not mention to proof and GS. Especially for the PAHs testing.

Mechanical: We had the experience of using recycled PVC materials in making some samples in animal shapes to test the mechanical performance. It can be easily broken down and it is hard to achieve the goal of detailed features, such as the fur of small animals.

The PVC material is already a low-tier kind of stuff. We don’t suggest customers use recycled PVC for their regular or official products, especially for toys.

Read more similar posts,

- Top Wholesale Markets in Southern China

- Made in China 2024: The Trends of China Manufacturing

- Ultimate Guide to New Product Development for Amazon Sellers

- Best-Selling Amazon Products You Can Import From China

- How to Import Building Materials From China?

Final Thoughts

In 2024 we will have more opportunities to engage with sustainable business, which is a great business to do.

We have the same global goals for sustainable development, and so does China manufacturing. Click here for more about how to benefit from China Manufacturing 2024.

Scientists are working on raw material analysis and keep trying to make biodegradable and sustainable materials to achieve the ultimate environmental sustainability.

Organizations like LEGO are sharing their social responsibility to use sustainable, biodegradable material products instead of traditional plastic products. We can see a great effort, and we have our hope for the future.

Do you have any comments to share about sustainable and biodegradable materials?

Leave us comments if you are interested in this post! Share it on social media!