Estimated reading time: 11 minutes

If you order certain products directly from some wholesalers or manufacturers, they may require a Minimum Order Quantity (MOQ) when you request their products.

Minimum Order Quantity (MOQ) refers to the minimum amount of any product a supplier is willing to sell to a buyer in a single order.

In the blog we have written, i.e. “How to Find Low MOQ Alibaba Supplier”, we also discussed the relation of MOQ with product price and quantity.

It is always a struggle to determine between the minimum order amount and the quantity you actually need. In this article, we are going to share some details on MOQ and give you some recommendations on how to discuss it with suppliers.

What is MOQ?

As I said at the beginning of this article, MOQ stands for Minimum Order Quantity. It is the smallest quantity of a product that a supplier is willing to sell.

Suppose you want to purchase 100 units of a product from a supplier, but their MOQ is 300. This means that the supplier may consider your quantity too small and be unwilling to sell the products to you.

Do not be concerned, for we will indicate in the latter parts of this article what to do in case you have less than the MOQ.

Perhaps you understand these suppliers, so you decide to purchase 300 units from them. At this point, your order quantity meets their set MOQ.

Minimum Order Quantity Define

MOQ is commonly used in trade, where many suppliers sell the same product. Some suppliers might have an MOQ of 300 units, while others may require an MOQ of 1000 units. The setting of MOQ can also be related to factors like cost or technological level.

All these indicate that before undertaking bulk purchases, it is advisable to select the correct supplier since your order quantity for the product must meet the supplier’s MOQ.

Here we have come up with a context between high MOQ and low MOQ.

| High MOQ and low MOQ | High Minimum Order Quantities | Low Minimum Order Quantities |

| Cost per Unit | Lower due to economies of scale. | Higher due to smaller-scale production. |

| Inventory Management | Potential overstocking; higher storage needs. | Easier to manage; lower storage requirements. |

| Flexibility | Less flexibility in responding to market changes. | More flexibility to adjust orders based on demand. |

| Suitable | It can be challenging for small businesses to meet. | More accessible for small businesses and startups. |

Why do manufacturers set a Minimum Order Quantity?

Firstly, we all know that suppliers also have a range of costs and other constraints, and they want to make a profit in trade. This is a key reason why MOQs are set—suppliers are unwilling to engage in business with too low or even negative profit margins!

The purpose of suppliers setting an MOQ is to sell more products in a single transaction. If you only purchase two or three units, the supplier will not reduce the price of the products for you, and they might even get upset.

Benefits and Challenges of MOQ

Minimum Order Quantities will impact your business. Let’s explore what benefits it can bring, as well as the challenges you might encounter.

The benefits for Suppliers,

- Ensured Profitability: When a supplier sets the MOQ for products, it means that this type of product can be produced on a large scale when an order is placed. On one hand, this increases production efficiency, and on the other hand, it also ensures that their costs and technology are adequately profited from in the transaction.

- Better Inventory Management: By setting MOQs, suppliers can predict and manage their inventory more effectively, minimizing the risk of excess stock.

- Streamlined Operations: Handling larger, consolidated orders simplifies logistical and administrative processes.

The benefits for Buyers,

- Lower Prices (Save your money): Larger order quantities often result in lower per-unit costs due to economies of scale. When you purchase just one unit of a product, the price per unit might be $5. However, when you buy at the minimum order quantity, the price per unit could drop to $3 or even lower!

- Stronger Supplier Relationships: Placing larger orders can lead to stronger relationships with suppliers, potentially resulting in better terms or priority treatment in the future.

- Consistent Supply: Meeting MOQ requirements ensures a consistent supply of products, aiding in smooth inventory management.

- Customization Opportunities: Suppliers may be more willing to customize products or packaging for orders that meet or exceed MOQs. After all, they also need to spend time and cost designing your product and starting up the machinery.

The challenges of MOQ,

- Reduced Flexibility: MOQs can limit a buyer’s ability to respond quickly to market changes or customer demands due to the commitment to large quantities.

- Risk of Obsolescence: In fast-moving markets, products purchased in large quantities may become outdated or irrelevant before they are sold. Typically, the Minimum Order Quantity set by suppliers may be higher than your purchasing quantity. So many buyers opt to increase their product procurement plans to accommodate the MOQ proposed by suppliers.

- Limited Supplier Options: For small businesses or startups, their funds are often limited, so excessively high minimum order quantity restrictions can result in a reduction in the number of suppliers they can work with.

- Quality Uncertainty: Many suppliers focus only on the quantity of product orders and delivery times, often neglecting the quality of the products, and they might even simply put the fragile products into plastic bags! I can’t imagine what the product will look like when it’s received!

Tip: Working With A Sourcing Agent

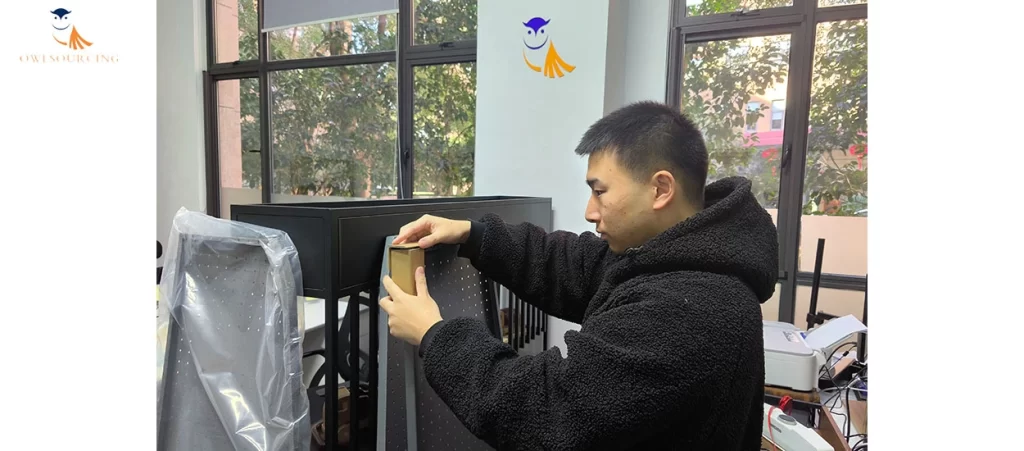

You might not be aware of how professional a sourcing agent can be. Owlsourcing will help you negotiate with suppliers to obtain the right MOQ and the lowest product prices, and they place great emphasis on quality inspection and packaging protection.

Owlsourcing Action ,

A member of the Owlsourcing team is enhancing the packaging dimensions of the product to ensure that it is not damaged during transportation.

This ensures that you smile when you receive the product – and of course, not a bitter smile, but a very satisfied one 🙂

Understanding MOQ Types: Simple vs. Complex Minimum Order Quantities

1. Simple MOQ: One Threshold Only

A simple MOQ is exactly that: one requirement to achieve before an order can be made. That could be:

- A minimum unit quantity (e.g., 500 units)

- A minimum total spend (e.g., $1,000 per order)

This kind of MOQ occurs in production-oriented industries where costs are needed for setting up, such as packaging or printing.

An example would be a custom book publisher requiring an order for a minimum of 200 books per run.

This is because calibrating the machinery, obtaining paper, and dealing with the order won’t pay for itself when ordering just 20 books.

2. Complicated MOQ: Various Conditions

Compound MOQs are several requirements that complicate it more for buyers to qualify, particularly if you are purchasing tailored or multi-component products.

Take the fashion industry, for instance. A clothing factory might require you to meet several levels at once:

- A number of units per design

- A number of fabrics length per color

- A minimum order amount (e.g., $5,000 per design)

In such instances, it is not sufficient to fulfill only one requirement. All requirements need to be fulfilled prior to production.

This is typical in industries where various inputs and processes (e.g., dyeing of fabric, cutting of patterns, sourcing of materials) need to be coordinated to maintain operations efficient and affordable.

Why Complex MOQs Need More Planning

Dealing with complex MOQs involves more than order forecasting, it involves intimate knowledge of your supplier’s cost structure.

That includes raw material costs, labor content, setup time, and even overhead like packaging or regulatory documentation. Without such transparency, buyers can be vulnerable to miscommunication, cost blowup, or order failure.

When qualifying a supplier, don’t only ask the MOQ, ask what goes into it. The better you understand their restrictions, the further up the mountain you can drive prices, aggregate orders, or invent around alternative options to meet their hurdles without cannibalizing your margins.

If you’re facing supplier MOQs in China or need help finding a factory appropriate for your level of production, our team at Owlsourcing can help bridge the gap with solutions tailored to fit your budget and growth stage.

What are the factors influencing MOQ?

When considering suppliers’ minimum order quantity, many factors can influence it. However, the main influences include material costs, production capacity, and order volume.

1. Material costs

Product suppliers need to handle their minimum order quantities within the supply chain. You can understand this as wholesalers needing to purchase finished products from suppliers. The factories that provide raw materials to these suppliers rarely have their own warehouses to store materials for them. Therefore, when suppliers consider costs, they include many aspects, such as storage fees and the labor costs of workers. All of these are factored into the material costs by the suppliers.

2. Production capacity

For large factories, they have advanced equipment and extensive production experience. This provides them with efficient production, but at the same time, it brings significant equipment maintenance costs.

As for smaller factories, because they only have poorer production equipment, they generally have longer production cycles and need to invest a lot of time costs. However, the good news is that you don’t have to spend a lot of money on their equipment costs.

3. Order volume

Order volume is at the heart of MOQ.

When these suppliers decide to sell their products, they consider where these products will be sold. For large customers or supermarkets, they will increase the minimum order quantity to sell more products.

Correspondingly, they will also adjust the product’s price. If selling low-profit products, they may require a higher MOQ to maintain a balance of income and expenses.

How to get suppliers’ MOQ?

My clients often ask me, “How to get suppliers’ MOQ?” To this, I simply tell them – the best method is to directly inquire with the suppliers.

Not sure how to write an email? Don’t worry, we have prepared email templates for you.

Subject: Inquiry about Product Range, Pricing, and MOQ

Dear [Vendor Name],

I hope this message finds you well. My name is [Your Name], and I represent [Your Company Name], a [type of business] based in [Your Country]. We specialize in selling [Products You Want to Carry], and we’re currently exploring new supplier partnerships.

We are particularly interested in the following products:

[Item 1: Description / Include photo if available]

[Item 2: Description / Include photo if available]

…

Could you please provide me with the pricing and availability for these items for quantities of 500, 1,000, and 5,000 units? Additionally, we would be grateful if you could share your product catalog, lead times for manufacturing, and the Minimum Order Quantity (MOQ) for these items. Additionally, I would like to ask, what is the minimum order quantity when we have customized products?

Looking forward to potentially working together and awaiting your prompt response.

Best Regards,

[Your Name]

[Your Position]

[Your Company Name]

[Contact Information]

What to do if you have less than the MOQ?

Please remember: Mutual respect can create room for both parties.

A sincere attitude may endear you to the supplier. When your order quantity cannot meet the supplier’s MOQ, try to communicate more with them or send emails.

If you want to wholesale 800 products, but the minimum order quantity is 1000, how should you communicate with them?

“I would like to order 800 pieces as a trial order. Please let me know the price, even if it might be different from the MOQ of 1000 pieces.”

Note: Please be aware that if you negotiate in this manner, be prepared for the supplier to increase the product price. However, they might only raise the price from $1 to $1.1 or $1.2, as mentioned earlier, since the price depends on the cost.

Another approach: If you might have larger orders in the future, you can sign an agreement contract with the supplier. This method ensures quality assurance before placing larger orders and will not increase the product price.

“Maybe I can meet the MOQ of 1000pcs, but I would like to split the order into two batches. I’d like to ship the first 400 pieces to check the quality and then order the second batch if the quality is good. Remember, quality is paramount.”

Of course, the number of products purchased from the supplier should not be too small either. For instance, if the supplier’s MOQ is 1,000 and you only want to purchase 50, you might be needed for you to switch to another supplier.

Final Thoughts

When we talk about Minimum Order Quantity (MOQ), many people struggle to find suppliers suitable for their purchasing volume.

However, overlooking the fact that satisfactory MOQs can be obtained through other means, such as communicating with these suppliers or contacting a sourcing agent.

Of course, if you wish to contact us or still have questions about MOQ, feel free to comment or send us an email at [email protected].

2 thoughts on “What is Minimum Order Quantity (MOQ)?”

I liked your article. Can you please explain the difference between MOQ and EOQ (economic order quantity)?

Hello Alex,

Thank you for your positive feedback on the article. Regarding your query, please allow me to provide you with an explanation.

MOQ (Minimum Order Quantity) is the smallest quantity a supplier is willing to sell, while EOQ (Economic Order Quantity) is the optimal order size that minimizes the combined costs of ordering and holding inventory.